CENTRIFUGE REPAIR, REBUILD, REFURBISHING, & RECONDITIONING

1. Arrival Process

Upon arrival machinery (decanter, tricanter, vertical cuttings dryer, basket centrifuge) is received at which time paperwork is immediately generated. This documentation reflects the arrival date, customer, point of contact, time of arrival, and the Job # that has been assigned to the repair or job. Detailed pictures are then taken from all elevations/planes of the equipment at time of its arrival and stored electronically. Job # is then stamped on all parts of the rotating assembly and any additional components applicable or where two components mate together.

2. Dissasembly

After all components including the gearbox are stamped with the newly assigned job number the disassembly process can begin. First the gearbox is removed and sent to the Gear Box department for further disassembly, cleaning, and inspection. Each component is then removed in reverse order of its general assembly and run through a parts washer.

3. Media Blasting/Cleaning

Once the largest majority of oils, greases and residual process build up have been removed via parts washer, each component is then vapor blasted for a more thorough cleansing. A sugar sand is used as the blasting media and is thoroughly cleaned from each part post vapor blasting process. This process does not cause damage to the passive layer nor alter the part's physical shape. Any worn coated components required to be vapor blasted will be recoated with a two part process prior to final assembly.

4. Inspections

A detailed inspection of each component is conducted post cleaning. Inspected and certified measuring tools are utilized to measure specific areas (bearing journals, seal journals, stack-up, stand-off, bore concentricity, register fits) so that these measurements can be cross checked against any corresponding/mating part or parts. Any and all findings are documented throughout the inspection report as well as each components measurement recorded. It is from this inspection we are able to develop the required parts list and hit list /scope of work. The completed inspection report is then supplied to the customer accompanied with the required parts list and formal quotation.

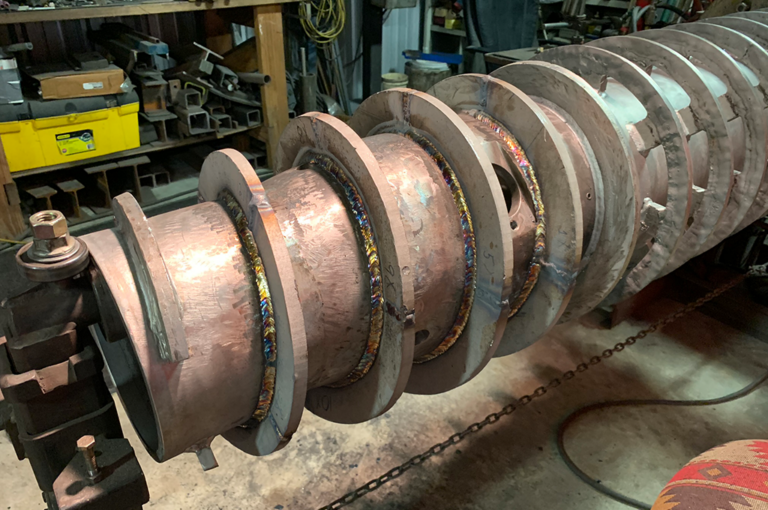

5. Conveyor Repair

Excessive wear to your conveyor can greatly diminish your solids capture rate. Our welding department is capable of building new conveyors, conveyor re blading, conveyor under cutting and tiling, re tiling, hard surfacing, conveyor hub build up, & performing conveyor modifications (re purposing a machine from one industry to another).

6. Welding

During the centrifuge repair various types of welding processes and procedures are performed in order to return machinery back to "As New" condition. Our welders are certified and capable of welding each of the following processes GTAW, FCAW, SMAW, GMAW. Our welding department is also outfitted with welding positioners, metal arc gouging, hard surfacing equipment, plasma cutting, and a flame spray powder rig.

7. Machining

In order to truly understand the physical condition of each component a manual engine lathe is utilized in the qualification process. Manual turning is undoubtedly our passion. Some of the Axelson manual engine lathes we have in service served on Naval carriers at some point in their youth. Today their purpose is to qualify individual machinery parts and hold .0005" tolerances when machining parts back to tolerance/specification. This qualification process allows us to ensure parts are on size within .0005” tolerance, maintain parallelism, maintain concentricity, as well as adjust stack up when necessary. All of these things are crucial for the centrifuge refurbishment.

8. Balancing

Balance is one of the most critical parts to the centrifuge repair. GreySun follows a strict SOP when it pertains to balancing. Our machine specific custom balancing tools are always qualified before each use. Two-plane dynamic balancing done the correct way, “In Realtime”. The balancing procedure we follow is simple. Maintain .002” TIR end to end of conveyor and balance utilizing window EZ balance 2.2 software. Once complete install conveyor into bowl and balance whole assembly with gearbox installed, pillow block assembly complete, and gearbox pinion held (scroll will be turning while balancing).

9. Assembly

Assembly compliments both the beginning, middle and the final stage of the centrifuge repair. As our first line of defense the assembly department is responsible for the disassembly and detailed inspection process which continues to serve as our guide throughout. Our assembly department is also the place where all parts returned to an "as New" condition are reassembled and balanced prior to function testing prior to delivery. Our mechanics stay in constant contact with the machinery and parts from the time it arrives until the last minute prior to its departure. This department has responsibilities such as disassembly, cleaning, inspection, flame straightening, two plane dynamic balancing, re assembly, precision measuring, and factory acceptance testing fall upon these craftsmen’s shoulders. Their passion for commitment and disciplined effort for centrifuge refurbishment is best shown in our delivered final product.

10. Reports

Detailed documents will be or have been created specifically for each make an model machine we work with. For all of our centrifuge repairs/equipment repairs a detailed inspection report is provided which denotes the physical condition of equipment upon arrival as well as the recommended scope of work required to return back to "As New" condition. Also accompanying the inspection report is the recommended parts list and formal quotation.

11. FAT/ QA/ QC

Prior to shipment of a completed centrifuge/equipment repair, it is a mandatory procedure for machinery to run at maximum operating speed for 2 hours. In 15-minute intervals temperature of pillow blocks/bearings, gearbox, & motor/s are checked and documented. Once Factory Acceptance Test is complete machinery is sent through make ready. The last and final step is the Q/A, Q/C check list. Upon its completion the paperwork is signed by site production mgr. At this time the centrifuge refurbishment/equipment repair is complete and ready for shipment.

12. Delivery

This is when you receive your completed centrifuge repair.